CNC machine technology is at the forefront of modern manufacturing, blending precision and efficiency to transform how we produce goods. From its inception to its current state, CNC technology has evolved dramatically, introducing a wide array of machines tailored for various industries. This technology allows for the automation of intricate tasks, ensuring consistent quality while reducing human error and labor costs.

As we delve deeper into the world of CNC machines, we’ll explore their diverse applications across sectors, the critical role of customer service in enhancing user experience, and the entrepreneurial opportunities they present. With insights into the ethical considerations and future trends, this discussion promises to illuminate the significant impact of CNC technology on the manufacturing landscape.

Introduction to CNC Machine Technology

CNC (Computer Numerical Control) machine technology represents a significant advancement in the manufacturing industry. It involves the use of computers to control machine tools that shape materials into desired forms. This technology has revolutionized how products are designed, produced, and maintained, offering precision and efficiency that were previously unattainable.The origins of CNC technology date back to the 1940s, with the development of the first numerical control systems.

These systems utilized punched tape to control machine tools. As technology progressed, CNC machines evolved to include computer systems that dramatically improved the accuracy and versatility of machining processes. Today, CNC machines come in various forms, including milling machines, lathes, plasma cutters, and 3D printers, each serving unique functions in manufacturing.

Types of CNC Machines

CNC machines can be categorized into several types, each designed for specific applications:

- CNC Milling Machines: Used for cutting and shaping materials, CNC mills can create complex parts and features with high precision.

- CNC Lathes: Ideal for producing cylindrical parts, CNC lathes rotate the workpiece against a cutting tool to shape it.

- CNC Plasma Cutters: These machines utilize plasma to cut through metal sheets and other materials with speed and accuracy.

- CNC Routers: Used primarily for woodwork, CNC routers can also cut plastics, composites, and soft metals.

- CNC Laser Cutters: Employing lasers for cutting, these machines are known for their precision and ability to work with a variety of materials.

Applications of CNC Machines

CNC machines are widely utilized across various industries due to their capability to produce complex parts with high precision. The technology enhances production efficiency, reduces waste, and allows for the creation of customized products.

Industries Utilizing CNC Machines

Numerous industries benefit from CNC machining, including:

- Aerospace: Producing critical components like turbine blades and structural parts.

- Automotive: Manufacturing engine blocks, chassis, and custom parts.

- Medical: Creating surgical instruments and prosthetics with high precision.

- Electronics: Fabricating enclosures, circuit boards, and other electronic components.

- Furniture: Designing intricate wood and metal furniture pieces.

Advantages of CNC Technology

Implementing CNC machines in production processes offers distinct advantages:

CNC technology significantly reduces production time, increases product accuracy, and enables mass customization, making it a vital asset in modern manufacturing.

Customer Service in CNC Machine Technology

Effective customer service plays a crucial role in the CNC machine industry, particularly during the selection and maintenance processes.

Importance of Customer Support

Having robust customer support ensures that clients can choose the right CNC machines tailored to their needs. Knowledgeable representatives can guide customers through the complexities of machine specifications and capabilities.

Best Practices for Customer Service

Providing exceptional customer service in this field involves:

- Timely Communication: Responding promptly to customer inquiries and concerns.

- Technical Expertise: Offering detailed technical knowledge and support during the purchase and installation process.

- After-Sales Support: Ensuring customers have access to maintenance and troubleshooting resources post-purchase.

Successful Customer Service Experiences

Numerous companies have demonstrated success through excellent customer service, resulting in long-term client relationships and repeat business. By prioritizing customer satisfaction, businesses can foster loyalty and gain a competitive edge in the CNC market.

Entrepreneurialism in the CNC Industry

The CNC machine sector presents a plethora of entrepreneurial opportunities due to its rapid growth and technological advancements.

Opportunities for Entrepreneurship

Individuals looking to venture into the CNC industry can explore numerous avenues, including:

- Custom Part Manufacturing: Offering tailored production services for various industries.

- CNC Machine Sales: Distributing CNC equipment and software solutions.

- Training Programs: Establishing educational initiatives to train new operators and technicians.

Innovative Business Models

Entrepreneurs are embracing innovative models, such as offering CNC machining as a service (MaaS), where clients can outsource their machining needs to specialized companies without investing in expensive equipment.

Successful Startups

Several startups have emerged in the CNC manufacturing space, capitalizing on niche markets and technological innovations to differentiate themselves from established players.

Business Ethics in CNC Operations

Ethical considerations are paramount in the CNC machine industry, influencing operations and customer relations.

Importance of Transparency

Businesses must conduct transactions with transparency and honesty to foster trust and reliability with clients and partners.

Implications of Unethical Practices

Engaging in unethical practices can severely damage a company’s reputation, leading to loss of business and legal repercussions. Maintaining high ethical standards is crucial for long-term success in the CNC industry.

Business Franchising in CNC Technology

Franchising offers a unique opportunity for businesses in the CNC machine market to expand their reach and brand presence.

Potential for Franchising

Franchising in the CNC sector can lead to increased market penetration and brand recognition. Franchisees can benefit from established business models and technical expertise.

Successful CNC Franchise Models

Several franchises have thrived within the CNC technology market, providing a roadmap for potential entrepreneurs seeking to enter this field.

Benefits and Challenges of Franchise Ownership

While owning a franchise can provide support and a proven model, potential franchise owners must also navigate challenges such as initial investment costs and adherence to franchisor standards.

Furnishings and Supplies for CNC Machines

Operating CNC machines requires specific supplies and furnishings to ensure efficiency and productivity.

Essential Supplies

A comprehensive list of essential supplies includes:

- Cutting Tools: Various tools according to the type of machining being performed.

- Coolants: Necessary for maintaining optimal temperatures during machining.

- Software: CAD/CAM software for designing and programming CNC processes.

Significance of Quality Materials

Utilizing high-quality materials in CNC production is vital for ensuring the durability and performance of the final products.

Sourcing Reliable Suppliers

Finding trustworthy suppliers is essential for acquiring the right equipment and materials for CNC operations. Building relationships with reputable vendors can enhance the overall production quality.

Human Resources in CNC Manufacturing

The skills and training of professionals working with CNC machines are critical to the success of any manufacturing operation.

Required Skills for CNC Professionals

Operators and technicians must possess a diverse skill set, including:

- Technical Proficiency: Understanding machine operation and basics of programming.

- Problem-Solving: Ability to troubleshoot issues that arise during production.

- Attention to Detail: Ensuring precision and accuracy in machining processes.

Training Programs

Various training programs exist to equip aspiring CNC professionals with the necessary skills, often offered by community colleges and technical schools.

Employee Retention Practices

Implementing best practices, such as ongoing training and competitive compensation, can significantly improve employee retention in the CNC sector.

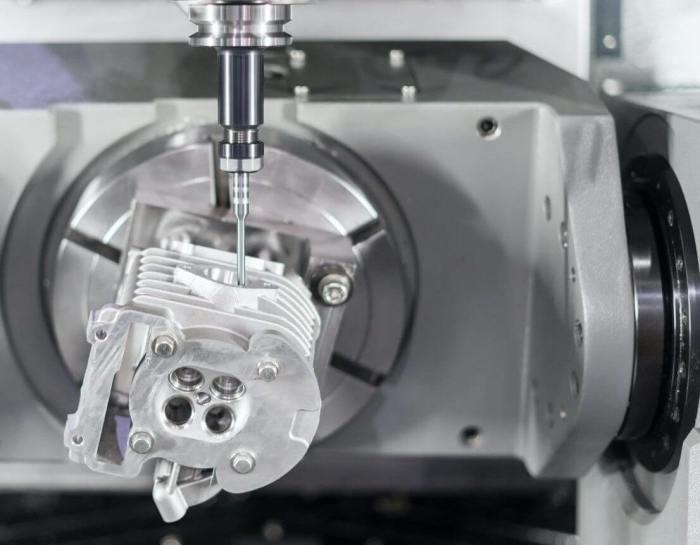

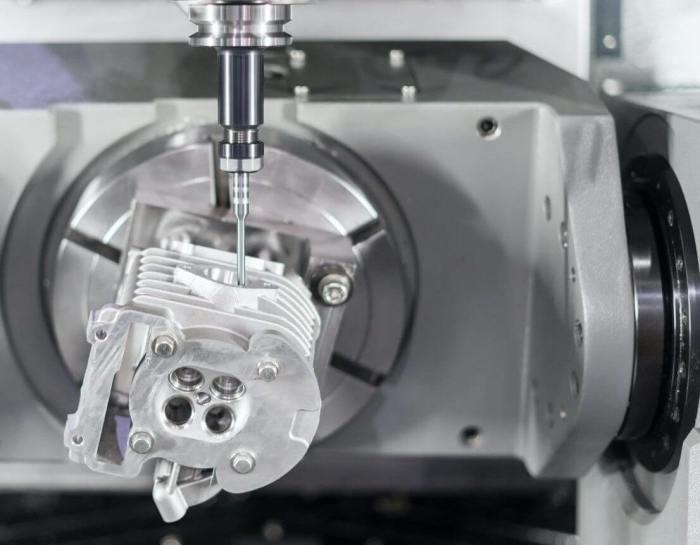

Industrial Mechanical Aspects of CNC Machines

Understanding the mechanical components of CNC machines is essential for effective operation and maintenance.

Mechanical Components

CNC machines comprise several key components, including:

- Frame: The structure that supports all machine components.

- Drive System: Mechanisms that convert rotary motion into linear movement.

- Controller: The brain of the CNC machine, interpreting commands from the software.

Operational Mechanics

CNC machines operate through a coordinated system of movements, allowing for precise machining based on computer-generated instructions.

Maintenance Procedures

Regular maintenance is critical to ensure optimal performance of CNC machines. This includes routine checks, lubrication, and part replacements as needed.

Future Trends in CNC Technology

The CNC industry is on the brink of substantial technological advancements that will shape its future.

Emerging Technologies

Innovations such as additive manufacturing and AI integration are revolutionizing CNC machining processes.

Impact of Automation

Automation is increasingly transforming CNC operations, enhancing efficiency, and reducing human error in manufacturing processes.

Market Growth Predictions

Experts predict significant growth in the CNC market driven by advancements in technology and an increasing demand for customized manufacturing solutions.

Final Summary

In conclusion, CNC machine technology not only revolutionizes production efficiency but also opens doors to innovative business opportunities and ethical considerations in the industry. As we look to the future, the continuous evolution of CNC machines and their integration with automation promises to further enhance productivity and transform traditional manufacturing practices. Embracing these advancements will be crucial for those looking to thrive in this dynamic field.

Query Resolution

What is CNC machine technology?

CNC machine technology refers to the use of computer-controlled machines to automate manufacturing processes, enabling precise and efficient production.

What industries commonly utilize CNC machines?

CNC machines are widely used in aerospace, automotive, electronics, and furniture manufacturing, among others.

What are the benefits of using CNC machines?

Benefits include increased accuracy, faster production times, reduced waste, and the ability to produce complex designs with ease.

How do I maintain a CNC machine?

Regular maintenance includes cleaning, lubrication, checking alignments, and performing software updates to ensure optimal performance.

Are there training programs available for CNC operators?

Yes, many technical schools and online platforms offer training programs focused on CNC machine operation and programming.